You might also be interested in

Not the right one?

E-Mail info@dietzel-hydraulik.de, Tel.: +49 36602 140-0

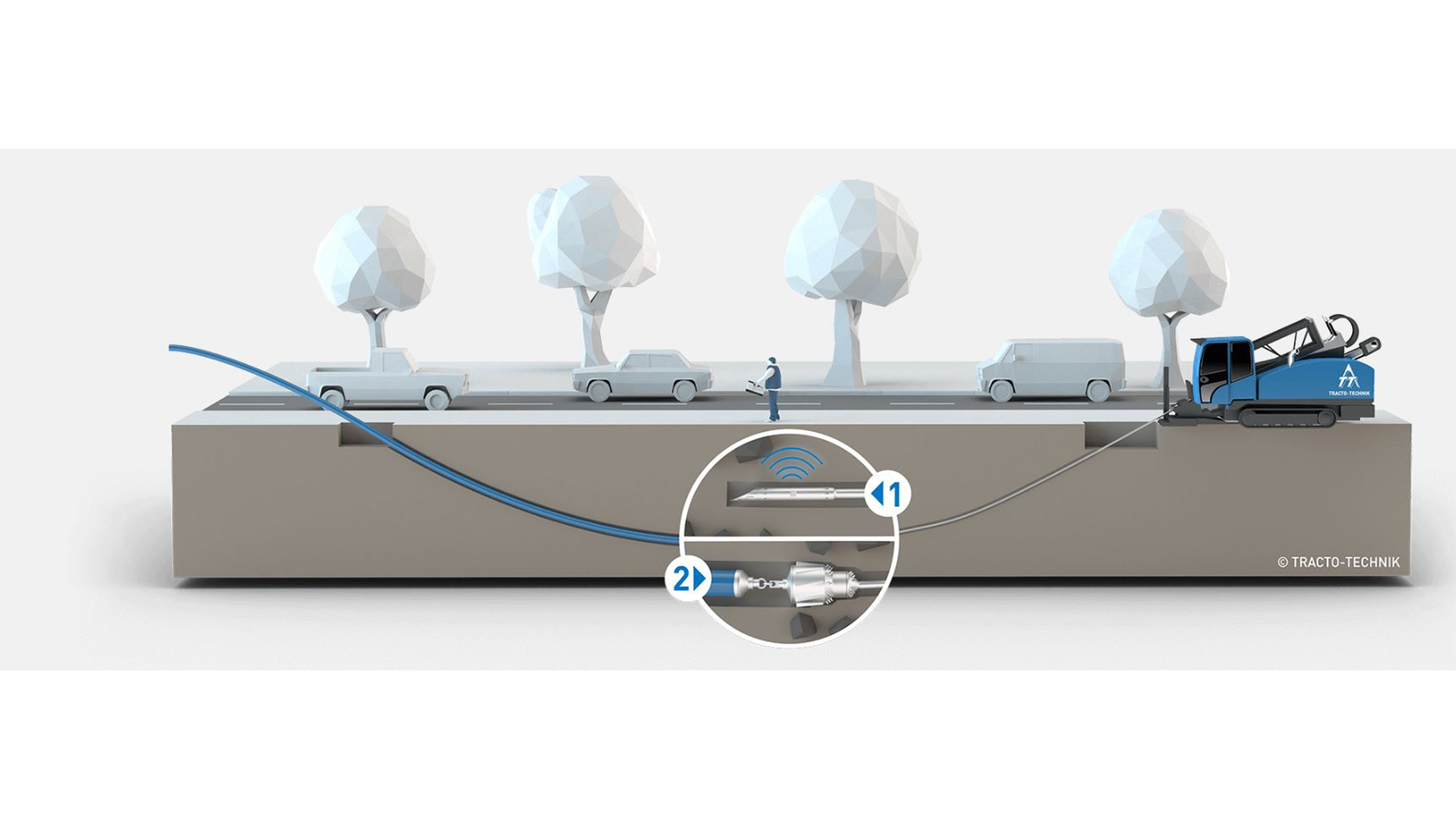

Whether for water pipeline construction, laying fiber optic networks, developing new natural gas distribution networks or district heating pipeline construction - there are many areas of application for trenchless pipe laying and the share compared with open trench construction is growing steadily. This is because the underground laying and renewal of supply and disposal lines offers serious technical and economic advantages. The elimination of excavation and reconstruction work as well as the shorter construction times are an enormous advantage, especially in the construction of house connections as well as in the crossing of heavily frequented traffic routes. "At the same time, the "mole technology" is also not entirely inconsiderable for the sustainability of our environment - the underground construction method leads to the avoidance of traffic jams, of detour and patching work, which reduces emissions of CO2 and fine dust," says Dieter Wurm, Design Engineer Prototype Construction & Testing at TRACTO-TECHNIK. TRACTO-TECHNIK has been specializing in trenchless installation technology since 1970, with a constant interest in optimizing its machines. But without functional hydraulics, there is no trenchless pipe-laying with controllable drilling rigs. "That's why it's important that we work with a reliable partner in the hydraulics sector - we have to be able to rely not only on the functionality of the products here, but also on the expertise of our hydraulics colleagues," Dieter Wurm continues. The company Dietzel Hydraulik can serve with almost as much experience - the specialist for hydraulic line technology knows only too well about the relevance of the quality of its products in daily use. The two companies have recently been involved in a highly exciting optimization project for the new generation of the hydraulically driven GRUNDODRILL horizontal directional drilling rig. TRACTO-TECHNIK has already been purchasing hose lines and protective hoses from Dietzel since the turn of the millennium and would now like to extend the cooperation to manifolds with the current project.

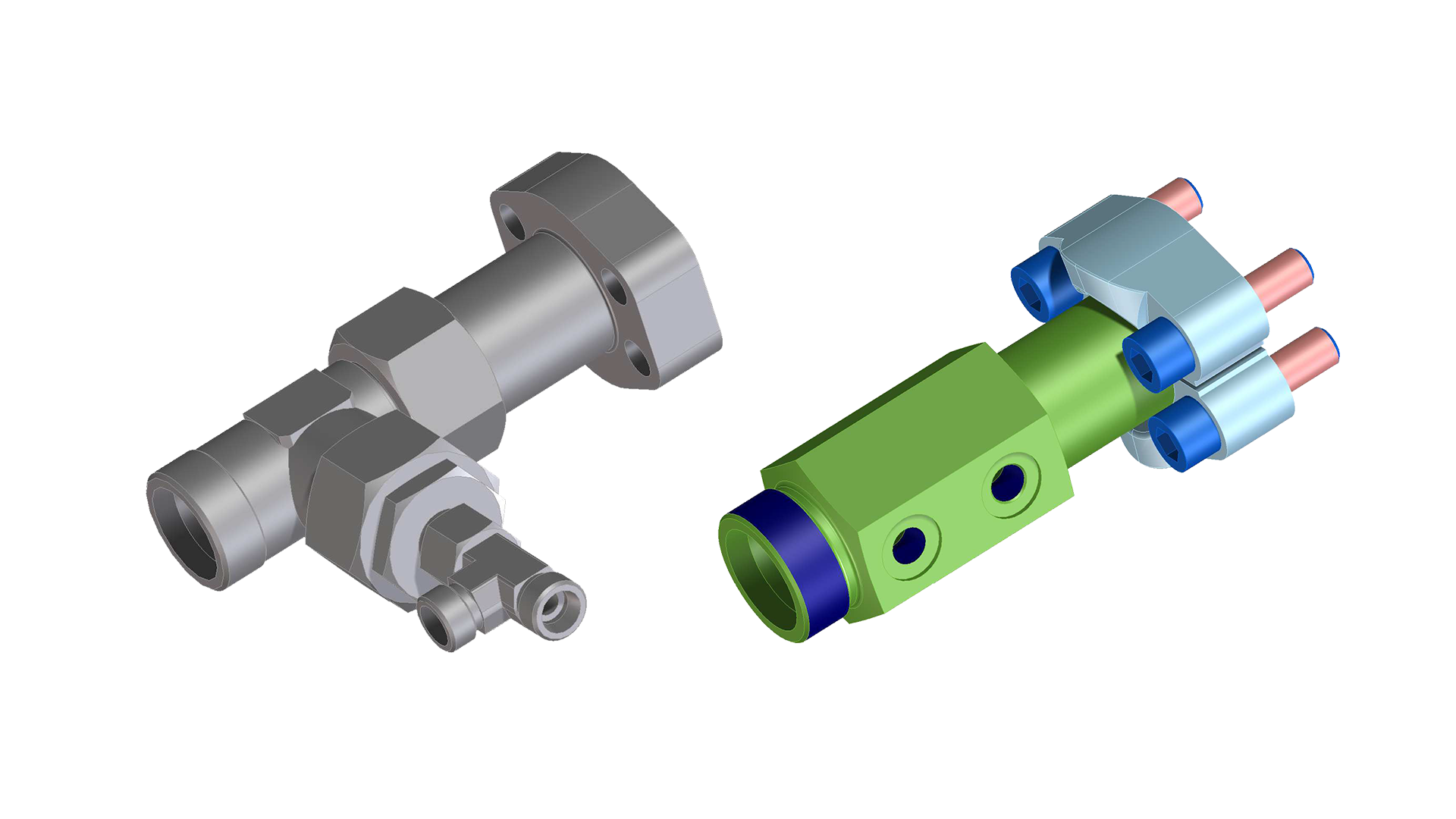

The concept of the new GRUNDODRILL generation is unique on the market with features such as fully remote controlled drilling operation. Long time in advance various optimizations were worked on. The subject of hydraulics was also to be given a "facelift". With the screwed chains previously used in the pump train, there is not only a risk of leakage and error, but the assembly and commissioning of the individual components also represents a high expenditure of time and money. With the appropriate engineering in the hydraulics sector, the long-standing TRACTO-TECHNIK partner Dietzel Hydraulik was able to optimize the existing bolted chains with functional bolting solutions. At the beginning of the project, the actual condition was analyzed on site by Dietzel engineers and customer advisors, and the existing 3D models were subsequently exchanged. Thanks to the know-how and many years of experience in the hydraulics industry, initial optimization approaches on the part of Dietzel were quickly found. In a few joint adaptation steps, the optimal bolting solution for the pump train of the new generation of the GRUNDODRILL was found, which also resulted in a standardization of the connections.

The advantages of the optimizations are obvious - with the adjustments, TRACTO-TECHNIK can produce more efficiently from now on, since fewer components have to be procured and commissioned. This in turn leads to much simpler article management - storage locations can be optimized or even saved. For the employees, the assembly of the pump of the new generation of the GRUNDODRILL has also been significantly simplified by the optimized components. "The susceptibility to errors decreases considerably," Dieter Wurm continues. But the biggest advantage is the almost completely eliminated risk of leakage when the machines are used by the end customer. With this screw joint replacement from Dietzel, the pump quality of the new GRUNDODRILL has been raised to a new level and drastically improved. This is made possible by the highly fl exible Dietzel modular system. From a large selection of subcomponents, customer-specific hydraulic solutions can be configured and manufactured in the shortest possible time. The advantage here is the fast response times in planning and execution. TRACTO-TECHNIK relies not only on the experience of Dietzel Hydraulik, but also on engineering and the necessary expertise to identify sustainable optimizations and reduce costs in the long term.